Add or Edit Stock Items |

Top Previous Next |

Watch the video: Creating New Stock Items - Tutorial

Hover the mouse over the different fields on the form. If the cursor changes to a hand (![]() ) , click to get more information.

) , click to get more information.

![]()

![]()

Add or Edit Stock Items

Overview

The Stock Items Management module in Smart-it allows users to add or edit stock items (products or services) that appear on invoices. It supports multiple methods for creating and updating items, importing data, and configuring inventory settings.

To add or edit a stock item, use one of the following methods:

1.Main Menu: Navigate to Stock Items > New Item.

2.Item Lookup: In Stock Items > Item Lookup screen, right-click an Item and select Open Inventory Form.

Methods to Create a New Item:

•Click on New Item in the Main Menu: You can also create a new item by clicking on New Item in the Main Menu. (see image above).

•Add New Stock Button: Go to: Stock Items > Item Lookup and click on the Add New Stock [F5] button.

•Import from CSV/Excel: Import stock items from a CSV or Excel file.

•Duplicate Existing Item: In Item Lookup, right-click an item and select Create A New Item Based On This Item.

Note: For new items, tabs are disabled until the form is saved.

Hover the mouse over the different fields on the form. If the cursor changes to a hand (![]() ) , click to get more information.

) , click to get more information.

Stock (Inventory) Item Fields Explained |

|

General Tab |

|

Status |

Reflects stock availability in PrestaShop (e.g., Supplier No Stock, End of Life, In Store, etc.).

|

Barcode |

Barcode - MPLU (Multiple Price Look-Up) The MPLU feature allows you to link multiple barcodes to a single stock item (maximum 25 characters per barcode). To add or edit barcodes, click the three-dot icon (

•Track a single product that has multiple pricing tiers. •Simplify stock control by avoiding duplicate entries for each price variant.

A list of multiple barcodes is available on the Stock Items > Item Lookup, click the MPLU Lookup button on the menu bar.

See also: Adding Different Units on how to add different units.

|

Item Name |

Maximum 255 characters. The 'Item Name' corresponds to the Prestashop Name. Supports column copy between the item name, short description and long description. Go to: Stock Extended Lookup >Change Selected 2 tab.

|

Short Description |

Maximum 500 characters. Short Description corresponds to the Prestashop Short description. |

Supplier |

|

Supplier Has Stock |

Supplier Has StockIf you do not have stock, but the 'Has CheckBox' is checked, then the description of the Supplier Has Stock will be used in the web shop.

Bulk change it in the Extended Item Lookup form. The supplier's inventory value can be retrieved either from their Web Service or via Excel, provided the supplier shares this data. The supplier's stock on hand quantity will appear in the Main Stock Form, To access it, click the Other Suppliers button.

|

Ordering Info |

|

Reorder Level |

Triggers reordering when stock reaches this level. Set in Stock Main Form. Options for managing the reorder level:

1. Average Sales Values: Set the reorder level to the average sales values in the Purchase Planning form. Use the With Selected (bottom of the form) the From/To fields. 2. Bulk Change: Bulk change the reorder level in the Extended Item Lookup form. 3. Default Value for New Items: Set a default value for new items in the Stock > Stock Options > New Item Defaults form.

|

Additional Order Quantity |

Quantity to order when reorder level is reached. This figure will be shown in the Purchase Planning Form. It is configured in the Stock Main Form > General Tab. You can bulk change the quantity in the Extended Lookup form.

|

Minimum Order Quantity (MOQ) |

Minimum quantity as specified by the distributor. Don’t confuse this with buying units or the units in a pack. For example, if you buy 1 box of pens containing 50 pens and you sell per pen, then your minimum quantity is one box. If in doubt, leave the minimum quantity as one!

|

Reliability % |

Accuracy of the suggested re-order quantity is.

|

Suggested Order Quantity |

Predicted order quantity based on max/min levels, lead time, and days until month-end. See the reliability % (row above) for the accuracy of the prediction.

|

Minimum Stock Level Maximum Stock Level |

Minimum Level: You will run out of stock if your stock goes below this level. Calculated as predicted next month’s sales ÷ 30.5 × supplier lead time. Manually adjustable unless Use Suggested Min/Max is enabled in Stock Options.

Maximum Level: Predicted max sales per month via regression analysis. Manually adjustable unless Use Suggested Min/Max is enabled.

Notes: These values are displayed in the Purchase planning form as Min Level / Suggested Min Level and Max Level / Suggested Max Level, as well as in the Inventory Statistics form. Bulk change the minimum / maximum levels in the Inventory Statistics form

You can change the above values manually in the Stock Main Form. To do this, go to Stock Options and deselect Use Suggested Min/Max Levels. |

Growth % |

Item Growth: Item Growth forecasts the average monthly increase or decrease in sales for each item. For example, a growth value of 8 indicates that the item's sales are expected to increase by 8 units per month.

This metric is used in Purchase Planning to optimize inventory management and ensure adequate stock levels.

|

Avg. Sales Qty. |

Average Sales Quantity: Recalculated per stock movement. Set months for calculation in Stock Items > Stock Group. Available in Stock Main, Purchase Planning, and Stock Extended Item Lookup.

|

Stock On Hand (SOH). |

Sometimes referred to as In-Stock. Stock on Hand (SOH):Total items in the store. Not all may be available for sale due to reservations for job cards and sales orders. The Available Quantity refers to the number of items that can be sold immediately.

|

On Order |

Items ordered but not yet received.

|

Reserved |

Reserved Quantities - SummaryReserved Quantities Reserved Quantities are the total quantities currently committed to Sales Orders, Jobcards, Production, BOM Components, and Warehouse Transfers (depending on your settings).

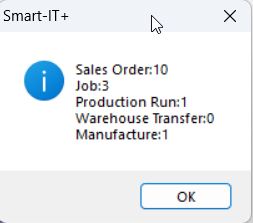

Formula: Reserved = Sales Order Allocated + Jobcard (if enabled) + Production Run + BOM Components (if enabled) + Warehouse Transfers (if enabled)

These values represent the global reserved quantity for an item.

How Items Become Reserved1. Sales Orders •Only allocated quantities on Sales Orders are counted as reserved.

2. Jobcards •Jobcards (only if Jobcard Reserve Stock is enabled) •Path: Workshop Options > Jobcard Reserve Stock

3. Manufacturing (BOM Components) To reserve BOM components: 1. Go to Stock Items > Stock Options >Manufacturing tab 2. Enable Reserve BoM Components

When enabled:

•Adding a BOM item to a Sales Order reserves the component items if there are not enough manufactured items available. •These reserved components will appear under Manufacture in the reserved breakdown (see image below).

4. Production Runs •Production Run items will reserve individual components if Reserve BoM Components is enabled. •Components from the Production Run display under the reserved breakdown.

5. Warehouse Transfers Warehouse Transfer reservation is optional: •If Stock Options > Warehouse Transfer > Reserve Stock is enabled: •Saving a transfer will reserve the stock until it reaches the receiving warehouse.

Automatic AllocationsIf you want the system to automatically allocate stock on Sales Orders: 1. Go to Stock Options > Allocation Tab 2. Enable Easy (Stock is not reserved)

Notes: •Reserved quantities only display when Advanced allocation options are enabled. •Easy mode does NOT reserve stock. To view the breakdown:•Click the question mark (?) to the right of the reserved field. This shows the exact source of all reserved quantities (Sales Orders, Jobcards, BOM, Production, Transfers). See image below

|

Uncommitted |

Uncommitted Quantities = In Stock - Sales Orders - Job Cards Displayed in Extended Item Lookup & Purchase planning Form |

Confirmed Demand |

Confirmed Demand = Total item quantities on Sales Orders and Job Cards. This is the quantity you need to fulfill all sales orders and job card requirements.

|

Available Quantity |

Quantity available to sell. Is the Stock On Hand - Reserved

|

Stock Shortfall

|

Is Confirmed Demand - (In Stock + On Order) A positive quantity means that you can't fulfill your current orders. |

See also Purchase Planning.

Inventory Quantity to Order |

Use either of these two, depending on your trust in the figures. |

Sugested Order Qty: Levels SQty.NoR (using your own values) |

If the In-Stock - Sales Orders - Reorder Level is less than or equal to 0, then the quantity will be calculated as follows: SQty.NoR = Reorder Level - In Stock - On Order + Confirmed Demand Otherwise, the calculation will be as follows: SQty.NoR= Reorder Level - In Stock + Additional Order Quantity - On Order + Confirmed Demand

|

Suggested Order Qty:Regression SQty.R (as predicted by SI+) |

Quantity to order using linear regression techniques. Suggestion Regression (SQty.R) = Next Sales + Confirmed Demand - On Hand - On Order |

Security Settings (You can set the following for this form)

View Restricted subset. (You can't see the fields)

Cost price, Supplier List Price and Supplier won't show

Edit tick. (If the tick is off you won't be able to edit the form)

Edit Restricted.

You can't edit the Supplier List Price.